Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

This sanitary weld rotating spray ball is designed to provide powerful and efficient 360-degree spray coverage for cleaning and sanitizing purposes. It features a stainless steel construction for maximum durability and corrosion resistance, is easy to install, and has an adjustable flow rate for different cleaning needs.

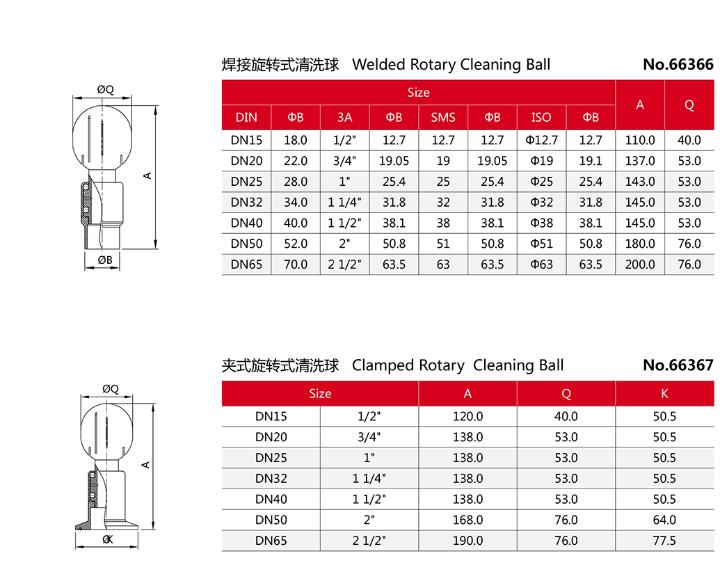

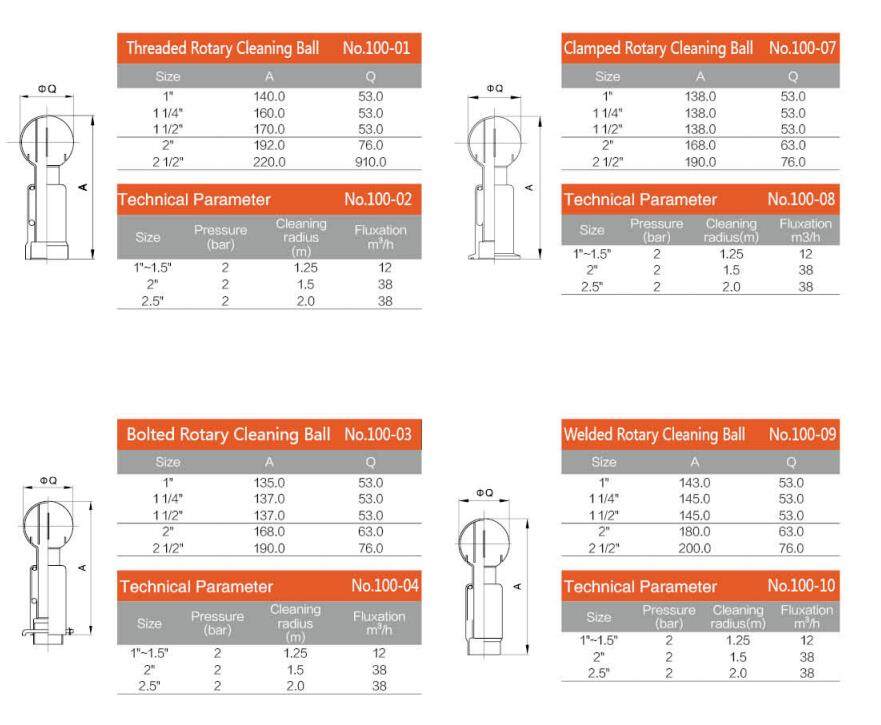

Product parameter

| Product Name | Sanitary Stainless Steel Welding Rotary Spray Balls with SS304 Material |

| Availably standard | DIN, SMS, RJT, ISO/IDF |

| Material Quality | AISI304(1.4301)/316L(1.4404) |

| Specificatio | 1"~2.5",Ball size19-63MM |

| Availabe Connection | Butt-weld,female threaded,male threding,tri clamped,bolt |

| Constructio | Rotary, Fixed,Double Rotary |

| Surface Treatment | Mirror Polished and Dull Polished,electro polished,ground finish |

| Pressure | .5~3bar ((14.5 - 44 psi) |

| Cleaning Radius | 1.25mm~3mm |

| Fluxation | 12~38m3/h |

| Spray angle/patter | 360-degree pattern |

| Temperature Range | -20degree Celsius~135degree Celsius |

The sanitary weld rotating spray ball is meticulously designed to meet the demanding requirements of sanitary cleaning applications. It features a compact and durable construction using high-quality stainless steel materials, ensuring longevity and resistance to corrosion. This rotating spray ball is specifically engineered to provide consistent and uniform spray patterns, ensuring complete coverage of surfaces during the cleaning process

Product drawing

Product Features

Application scenario

Product Advantages

1.Thorough Cleaning: The rotating spray ball provides thorough and efficient cleaning of tanks, vessels, and pipelines. The rotating spray patterns ensure complete coverage and eliminate the risk of missed spots or uneven cleaning results.

2.Time and Cost Savings: The rotating spray ball’s efficient cleaning performance reduces cleaning time and saves on labor costs. Additionally, its durable construction and low maintenance requirements contribute to overall cost savings in cleaning operations.

3.Hygiene and Product Quality: The rotating spray ball’s hygienic design and thorough cleaning capabilities contribute to improved hygiene and product quality. It eliminates contaminants and residues, ensuring the integrity and safety of the processed products.